1. Prevent short circuits : Avoid internal wire shorting.

2. Prevent electric shocks : Ensure personnel safety.

3. Improve efficiency : Reduce energy loss.

4. Withstand high voltage and temperature : Ensure stable operation.

5. Extend lifespan : Prevent overheating and premature aging.

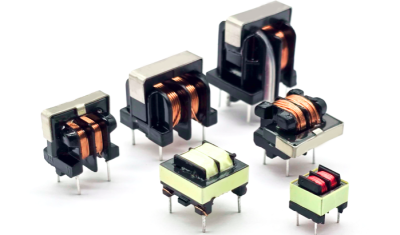

Insulation methods for electronic transformers mainly include :

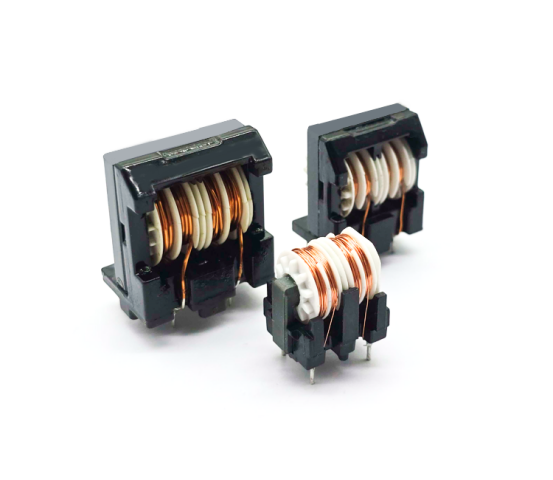

1. Enameled wire/Triple insulated wire : Prevent short circuit between windings.

2. Insulation tape : Adds additional insulation protection.

3. Potting : Encapsulate with epoxy resin or silicone to improve insulation and moisture resistance.

4. Dipping : Strengthens insulation.

These methods can enhance the insulation performance and durability of transformers.

Insulation System Class

Insulation materials in power transformers are susceptible to aging and damage due to high temperatures. Different insulation materials have different thermal endurance properties, so power transformers have a specified maximum operating temperature.

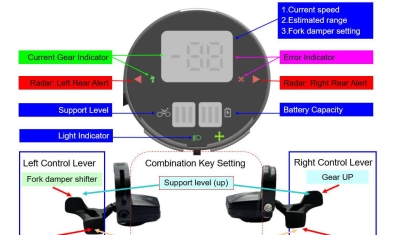

The common insulation system classes are as follows:

| Operating Temperature | Y | A | E | B | F | H |

| Classe | 90°C | 105°C | 120°C | 130°C | 155°C | 180°C |

Certification can be obtained through UL's insulation systems as needed. Currently, ATECH OEM INC. Insulation Systems include Class B (130°C) and Class F (155°C).